Applying heat is a critical step in auto glass installation, ensuring a secure fit through controlled warmth delivery using specialized equipment. This process involves preparing the car body, gradually heating the glass with tools like heat guns, and adhering to manufacturer guidelines. Heat softens the edges of the glass, facilitating precise fitting within the vehicle's frame and creating an airtight seal for enhanced structural integrity and water resistance. Post-installation heat treatment further improves shock and temperature resistance, making the new glass seamlessly integrate with auto body services for a robust, safe finish. This method offers key advantages, especially for complex vehicle models, by softening the glass for perfect conformity and enhancing sealant adhesive properties for improved impact resistance.

Applying heat during auto glass installation is a crucial step that ensures a seamless, durable fit. This article guides you through the entire process, from understanding the science behind it to mastering the techniques. We explore how heat facilitates the glass’s flexibility, allowing it to conform perfectly to your vehicle’s contour. Learn about essential tools, safety precautions, and surface preparation to achieve accurate and efficient heat application.

- Understanding the Heat Application Process

- – The role of heat in auto glass installation

- – Benefits of applying heat during installation

Understanding the Heat Application Process

Applying heat is a crucial step in the auto glass installation process, ensuring a precise and secure fit. This technique involves using specialized equipment to deliver controlled warmth to the glass and the car body surrounding it. By doing so, the glass becomes more pliable, allowing it to adhere effectively to the vehicle’s frame. Heat application is not merely about heating up the glass; it’s an art that requires skill to prevent over-heating, which could lead to damage or warping.

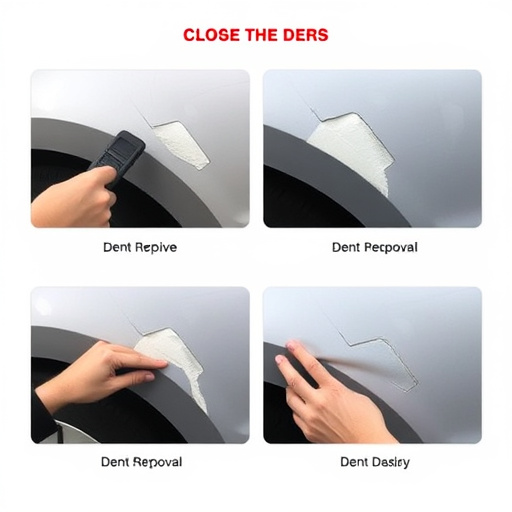

The process typically begins with preparing the car body for installation by ensuring the area is clean and free of debris. Then, heat guns or other heating tools are used to apply warmth gradually, following the manufacturer’s guidelines. This careful approach facilitates a seamless transition as the glass expands and contracts during heating and cooling, ultimately resulting in a perfect fit, enhancing both the structural integrity and aesthetic appeal of auto glass installation, much like restoration of a car body after dent removal or meticulous paint jobs.

– The role of heat in auto glass installation

During auto glass installation, heat plays a pivotal role in ensuring optimal performance and durability of the new glass panel. The application of controlled heat helps to facilitate a seamless fitment by softening the edges of the glass slightly, making it easier to align and secure within the vehicle’s frame. This process also ensures an airtight seal, which is crucial for maintaining the vehicle’s structural integrity and preventing water penetration.

Furthermore, heat treatment after installation enhances the glass’s resistance to shock and temperature changes, a significant factor in auto body repair and maintaining the overall safety of the vehicle. This step is often part of comprehensive auto body services, contributing to the overall quality of car paint repair and ensuring the new glass seamlessly integrates with existing repairs for a robust finish.

– Benefits of applying heat during installation

Applying heat during auto glass installation offers significant advantages for a seamless and secure fit. The process facilitates the softening of the glass, allowing it to conform more easily to the car’s curves and contours. This is particularly beneficial for complex vehicle models with intricate window shapes, ensuring the glass adheres perfectly without gaps or misalignments.

Moreover, heat application enhances the adhesive properties of the sealant used in auto glass installation. As the glass heats up, the sealant becomes more fluid, promoting better contact between the glass and car body, which is crucial for resisting impact and water penetration. This technique is also valuable for car restoration projects, where replacing windows can be a meticulous task. Heat treatment streamlines the process, making it faster and more efficient while maintaining high standards of quality, much like when tackling dent removal to restore a vehicle’s original aesthetics.

During auto glass installation, heat application is a crucial step that enhances the process’s efficiency and durability. The heat not only facilitates the proper alignment and sealing of the glass but also ensures a secure fit, improving the overall safety and performance of the vehicle. By understanding the benefits of heat application, automotive professionals can deliver high-quality installations, ensuring smoother drives and enhanced customer satisfaction for auto glass replacement or repair services.